Loworange88

.40 S&W

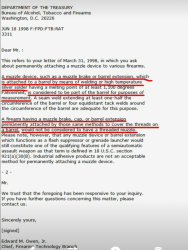

Hey everyone. Is there anyone in the Syracuse area that can permanently fix a thread protector on a barrel for a reasonable price? I'm not sure of the correct process, ie: pin and spot weld, spot weld only, silver solder, or some sort of chemical bond...

Thanks.

Thanks.