This thread is to document the making of my Carry V10. It is the blending of a full sized government model 1911 (with rounded butt) to a 3” Springfield V10 slide and barrel in 45 ACP.

the barrel has a Wilson/Nowlin ramp so to make things easy I picked up an 80% frame with the feed ramp already cut for a Wilson/Nowlin barrel.

1 first step was decking the frame this is done to ensure the slide will sit where it is supposed to in relation to the disconnector, hammer and frame. If you don’t deck it before you cut the frame rails you will need to get a new frame or weld it up and start over.

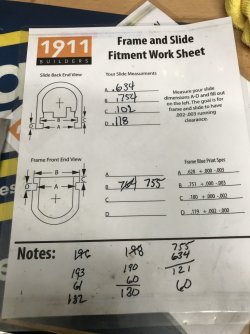

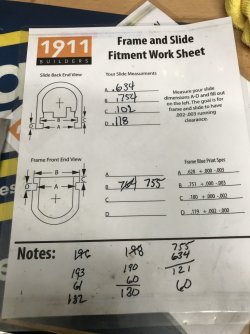

2. Second step is measure both the slide and the frame so you know what to cut and when to stop cutting.

3. Third step is drill the hammer and sear pin holes.

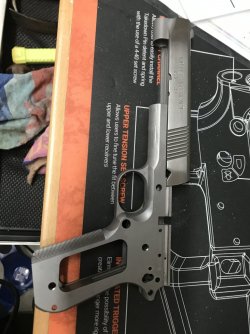

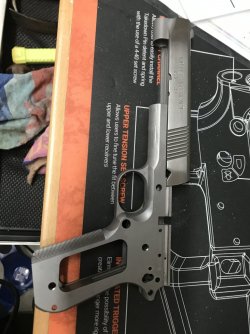

4. Fourth step is cut the frame rails.

5. Fit the slide to the frame.

I am on step five and stopping for the evening.

the barrel has a Wilson/Nowlin ramp so to make things easy I picked up an 80% frame with the feed ramp already cut for a Wilson/Nowlin barrel.

1 first step was decking the frame this is done to ensure the slide will sit where it is supposed to in relation to the disconnector, hammer and frame. If you don’t deck it before you cut the frame rails you will need to get a new frame or weld it up and start over.

2. Second step is measure both the slide and the frame so you know what to cut and when to stop cutting.

3. Third step is drill the hammer and sear pin holes.

4. Fourth step is cut the frame rails.

5. Fit the slide to the frame.

I am on step five and stopping for the evening.