You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to check AR build Head Space w/o go nogo gauges.

- Thread starter FRB

- Start date

Grab a single round, toss that bitch in send the bolt home, take off safe and fire

kev74

20×102mm Vulcan

I've seen some guys use tape on the bottom of a cartridge to measure headspace.

Pull the extractor off the bolt, then close the bolt on the cartridge with successive layers of tape added to the cartridge until resistance to the bolt locking is felt. Then measure the tape thickness.

Pull the extractor off the bolt, then close the bolt on the cartridge with successive layers of tape added to the cartridge until resistance to the bolt locking is felt. Then measure the tape thickness.

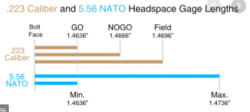

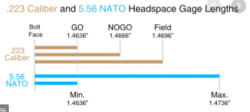

The only way to really do it properly is with the go/no-go/field gauges. Any other way you’re really only guessing. Do you want to be guessing with how much money you just spent on parts just to have it possibly explode, destroying the parts or even worse injuring you? I’ve seen people put casings in and if it closes they think they’re good to go, which is not the case. The minutia of measurement is not able to be done with an empty casing, paper, or tape safely. You know how thick the average sheet of paper is? It’s .0039 inches thick. That’s almost 4x larger than the difference between what a .223 go gauge and a 5.56 go gauge are. You’d be willing to bet your health and gun parts on something that has too many variables to be able to tell if it’s correct? Is the shell casing that you’re using the proper dimensions, do you know if your barrel is within the proper measurements, same thing for your upper receiver, or bolt. All the parts on their own could be within the proper specifications but when you put them together they end up not working together due to tolerance stacking. I’d say get the gauges or have someone do it properly for you.

BMF JK

.44 mag

Grab a single round, toss that bitch in send the bolt home, take off safe and fire

works every time

libertysnake

.338 Win Mag

The only way to really do it properly is with the go/no-go/field gauges. Any other way you’re really only guessing. Do you want to be guessing with how much money you just spent on parts just to have it possibly explode, destroying the parts or even worse injuring you? I’ve seen people put casings in and if it closes they think they’re good to go, which is not the case. The minutia of measurement is not able to be done with an empty casing, paper, or tape safely. You know how thick the average sheet of paper is? It’s .0039 inches thick. That’s almost 4x larger than the difference between what a .223 go gauge and a 5.56 go gauge are. You’d be willing to bet your health and gun parts on something that has too many variables to be able to tell if it’s correct? Is the shell casing that you’re using the proper dimensions, do you know if your barrel is within the proper measurements, same thing for your upper receiver, or bolt. All the parts on their own could be within the proper specifications but when you put them together they end up not working together due to tolerance stacking. I’d say get the gauges or have someone do it properly for you.

Yeah when in doubt, check with a gunsmith or manufacturer.

Even when I swapped the bolt carrier on my AK, which the manufacturer supplied a replacement and said headspace wouldn't be affected, I still checked with go/no-gos.

Like I’ve previously stated somewhere on this forum. I was building an AR not too long ago where the bcg closed completely in the chamber like it’s supposed to (like 99% of BCG’s will do when just chucking them into an upper). But when I went to actually check headspace it would not close on a go gauge like it should have. So I tested the BCG in another AR which I know the barrel is correct and the BCG closed properly. Sometimes checking headspacing doesn’t diagnose just and out of spec bolt. It’s not even like the out of spec barrel was from a untrustworthy company, it was from Wilson Combat. I had to contact them and send it back so they can send me a new barrel.

Just use milspec and everything will be fine

meketrefe

.450/400 Nitro Ex

If one has a no-go gauge that is all one needs. then make sure that it also chambers with all the brass and a go gauge if one has that one too

but the gauges are not 100% necessary.

One can headspace a gun with full resized/formed brass as precisely or better as any gauges.

One just needs to know exactly how but more importantly why we are doing it this way.

It is not unusual for BR shooters to headspace rifles to the precise dimension of the brass that comes out of their press of from their favorite manufacturer. A hih end rifle maker can cut a barrel and chamber true SAAMI or even tighter than that. But a regular sporting rifle is going to have a tad more tolerances and therefore easier

for wide range of loads including service ammo for all over the place clean or dirty and it has to be safe. Also for a simple safety check as the op needs this process doesn't have to be so involved but it has to be done correctly.

In order to make sure the chamber is safe, head-spacing is just one of the checks one has to do. A rifle with a short tenon can have a perfect

headspace yet be totally unsafe to shoot.

Before one starts one is going to need to strip the bolt, remove the firing pin, extractor and ejector plunger and give both bolt and chamber

a good cleaning and totally dry. In an AR this is best done with the barrel off the upper receiver before installing.

Also a couple of Full Length sized cases, maybe some favorite round with one round that we can deactivate by pulling

the bullet very carefully and emptied. If folks have a press and FL dies that is ideal.

We are going to assume you are jus tdoing the field and safety checks from an already chambered and headspace barrel but otherwise if you are actually cambering let us know because one has to follow a few more steps.

We will also need a cleaning rod, some aluminum tape or thin mask tape and a razor and ideally calipers, that every shooter should have.

I will explain in detail tomorrow or over the weekend. today we finished work very late and I am toasted, both sides.

Stay tuned.

but the gauges are not 100% necessary.

One can headspace a gun with full resized/formed brass as precisely or better as any gauges.

One just needs to know exactly how but more importantly why we are doing it this way.

It is not unusual for BR shooters to headspace rifles to the precise dimension of the brass that comes out of their press of from their favorite manufacturer. A hih end rifle maker can cut a barrel and chamber true SAAMI or even tighter than that. But a regular sporting rifle is going to have a tad more tolerances and therefore easier

for wide range of loads including service ammo for all over the place clean or dirty and it has to be safe. Also for a simple safety check as the op needs this process doesn't have to be so involved but it has to be done correctly.

In order to make sure the chamber is safe, head-spacing is just one of the checks one has to do. A rifle with a short tenon can have a perfect

headspace yet be totally unsafe to shoot.

Before one starts one is going to need to strip the bolt, remove the firing pin, extractor and ejector plunger and give both bolt and chamber

a good cleaning and totally dry. In an AR this is best done with the barrel off the upper receiver before installing.

Also a couple of Full Length sized cases, maybe some favorite round with one round that we can deactivate by pulling

the bullet very carefully and emptied. If folks have a press and FL dies that is ideal.

We are going to assume you are jus tdoing the field and safety checks from an already chambered and headspace barrel but otherwise if you are actually cambering let us know because one has to follow a few more steps.

We will also need a cleaning rod, some aluminum tape or thin mask tape and a razor and ideally calipers, that every shooter should have.

I will explain in detail tomorrow or over the weekend. today we finished work very late and I am toasted, both sides.

Stay tuned.

Last edited:

meketrefe

.450/400 Nitro Ex

Calipers on hand and with the other components it is time to check that chamber.

The reason we remove the extractor and ejector plunger is to have a true measure w/o interference of external parts that are not the base of the bolt, the chamber and the brass. As you know the ejector plunger pushed the case forward so that would not be an accurate measure of any kind.

If one had to leave something the extractor would fine as soon as we position the brass hooked inside the extractor and fish it inside the chamber so there is force involved in extractor claw going over the case rim.

This is why the ideal way to do this operation is with the barrel off the action and with just the bolt piece and w/o any other interference.

I suggest two or three pieces of brass that one could keep as 'poor man gauges' for this caliber and after this. The same idea as field gauges through history that served as a way to have an inexpensive gauge made of an inexpensive alloy to verify chambers were no longer than the absolute maximum allowed for a service rifle.

FIRST CHECK IS EASY

There is no one single good method for this but this could be one easy way...

A) take a piece of new full length resized brass and lets keep this one for this check. If the brass is once fired make sure is cleaned, resized and specially remove any burrs or extrusion marks from the base of the brass before resizing by using a fine file or sandpaper. any extrusion where

the plunger might have put a "bite" on the brass might create a ridge that doesn't make the whole face of the brass smooth. also marks in the rim

form the extractor. So in this case the first thing would be just to sand it so slightly and even the edge of the rim if there are any extractor bites.

Same if we want to trim the brass a bit to make it uniform at the mouth.

So after we have a perfectly smooth and bright and full sized brass (a couple of them will be fine. )

B) we can introduce the brass into the chamber that should just drop in. (plunk test).

C) We introduce the bolt as designed and rotate the bolt to go into battery. with our two finger there should not be any resistance of any kind.

notice that the bolt must be closed and pushed back (in this case pulled) that is the same effect the pressure from firing a round has to make

sure all lugs are in contact with the lugs as the bolt is pushed back into the battery position.

D) WE can rotate the bolt back and open and if we tap the inserted round it should drop right off. if not it can be gently pushed from the muzzle with a dowel or cleaning rod w/o damaging the crown or anything.

One could repeat this process with other cases including cases from our favorite manufacturer after pulling the bullet and empty the powder. I am not going to suggest to use a live round even there is no firing pin or anything that could cause a problem but everyone needs to know what feels safe or not and what ammo one wants to test.

AT THIS POINT, AFTER A FEW CHECKS WE KNOW THE CHAMBER IS LARGE ENOUGH FOR RELOADS AND/OR STANDARD FACTORY AMMO BUT WE HAVE NOT COMPLETED ALL SAFETY CHECKS YET.

NEXT...

1) After we do the above we are going to take one of the cases and drop it again in the chamber.

2) With the help of a flashlight or good lighting in the room we are going to verify that the chamber covers the entire case with the exception

of the rim.

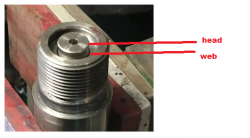

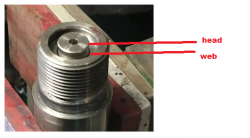

A well supported case has a chamber that covers the entire web and obviously leaves a space for the bolt and extractor to work.

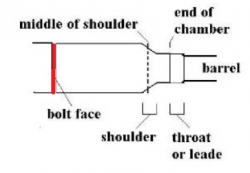

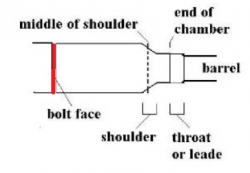

In other words, while we are doing the headspace we should also check on the chamber length to make sure that is also safe.

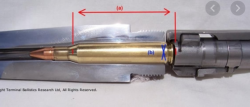

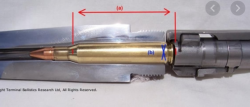

The headspace in a 5.56 is measured from the shoulder to the base (a) in picture but we also want to make sure we have enough

of the web that is inside the chamber. making a tenon too short is not something you see often but I have seen a cheap AR barrel

from PSA wiht a short tenon mistake that was not safe and the cases will buldge at the web and even the shooter was lucky not to

have one fail but hey was having all sort of extraction problems.. (not having enough of (b) X in blue support in picture below)

SO AFTER THIS WE WILL KNOW THE CHAMBER IS SAFE HAVING A LONG ENOUGH BARREL TENON AND CHAMBER TO SUPPORT THE CASE.

But we are not done yet. Now we have to make sure the chamber is also NOT TOO LARGE for the brass.

A) Take one of the FL formed brass and cut a piece of aluminum tape that should be around 2-3 thousands in thickness. you can measure the tape or you could simply measure the case with the calipers, add the tape and then cut around with a razor to make it perfectly round and flat and the measure again with the calipers. After adding 2 or 3 pieces of tape and depending on the length of the original sized brass one might have added 4 to 6 thousands that is measurable with the calipers. difference between the original measure w/o any tape.

B) In every step added we drop the case inside the chamber and proceed as above. We might not go above a certain length difference from the

brass that chambered.

WE just have to make sure the space between the base of the case and the bolt is not excessive after chambering. red space in picture below.

In military rifles this is larger than a match rifle to account for differences in service brass from all over, debris, weather, wear, etc...

and while brass is safe to expand a tad we want to make sure it doesn't go beyond a given point.

C) We will add tape and cut around and repeat as needed.

Because rifles of the same calibers can have different actual chambers some a tad shorter and some a tad longer it doesn't mean anything but also why 5.56 might be on the loose side to be more forgiving and reliable...

So this means 223 might have up 6 thousands or even less, at some point THE BOLT SHOULD NOT ROTATE INTO BATTERY!!! If you have added 6 or 8 thousands (max extreme being 10 thousands from min) and still close that is too large of a chamber. Ideally you do not even get to 6 thousands before you feel the bolt not wanting to close. at 8 thousands it should not close at all.

2 gauges with 6 thousands tolerance between a go chamber and no go. This is what is the minimum safe

for 223 as seen above but also used for 5.56 in many civilian chamberings.

IMPORTANT

This is also a tad relative because if you are using 2 or 3 pieces of brass you might want to size them all the same or

perhaps get a factory one and then find out what the differences are between those before start by measuring the

cases but you cannot measure the case from the mouth so use a case gauge or a small pistol case to create a stop

at the shoulder and measure relative differences.

Ideally the a case 'comparator' is the best way same with bullets that should be compared relative to the datum.

AT THIS POINT YOU SHOULD KNOW IF THE CHAMBER IS NOT TOO LARGE AND THEREFORE SAFE TO USE.

CONSIDERATIONS:

Alternatively to the tape measure one might fill out a case with hot glue or epoxy and/or a plastic dowel so one could thread

the thread end of a cleaning rod. This doesn't have to be too strong but it has to be secured and w/o play.

One will have to insert the cleaning rod and then thread the case into it and then push the case with the rod inside the chamber.

They key is that this is a firm fit and there is no any play between the case and the rod when pulling and pulsing so slightly.

Then, after closing the bolt and holding the bolt back by pulling (lugs againsts lugs) one could measure the difference in headspace

with one case by holding the bolt closed and then moving the rod and case front to back and marking with a razor flush by the muzzle in the cleaning rod. The difference between pulling and pushing on the bolt with that case we will see two marks in the rod. you can put some tape

at the muzzle and see the razor cuts there as marks that should be no longer than 6 thousands ideally.

The difference between those two marks will be the tolerance. In a tight chamber one might feel zero movement when pushing and

pulling so slightly.

One could even fill the case with sugar after putting a spent primer and leave enough space to seat a solid copper bullet backwards

that could be drilled and tapped with the same thread from the cleaning rod add glue so it doesn't move. Not a free imrpovised gauge

but not too expensive or hard to make.

There are several other methods that could give a pretty accurate measure in order to determine the tolerances inside the chamber.

Needless to say, if one is not mechanically oriented or doesn't have skills and minimum understand of mechanical things, this might feel

a strange process and one will be better checking with a gunsmith or someone who understands head-spacing like people who swap

barrels in a savage rifle between seasons. With a savage one can make the headspace really tight for ones competitions and/or hunting

and headspace to zero tolerances with once reloads or favorite factory ammo. This might mean some ammo will feel sticky going in

or even will not chamber. And that is why in service rifles, sporting guns the barrel makers give a tad more headspace to be more reliable

with a wide range of ammo and conditions.

Here is an example of someone making a very short chamber using tape to give about 2thousands longer than the go gauge.

This is obviously a very tight chamber for match type of use.

The reason we remove the extractor and ejector plunger is to have a true measure w/o interference of external parts that are not the base of the bolt, the chamber and the brass. As you know the ejector plunger pushed the case forward so that would not be an accurate measure of any kind.

If one had to leave something the extractor would fine as soon as we position the brass hooked inside the extractor and fish it inside the chamber so there is force involved in extractor claw going over the case rim.

This is why the ideal way to do this operation is with the barrel off the action and with just the bolt piece and w/o any other interference.

I suggest two or three pieces of brass that one could keep as 'poor man gauges' for this caliber and after this. The same idea as field gauges through history that served as a way to have an inexpensive gauge made of an inexpensive alloy to verify chambers were no longer than the absolute maximum allowed for a service rifle.

FIRST CHECK IS EASY

There is no one single good method for this but this could be one easy way...

A) take a piece of new full length resized brass and lets keep this one for this check. If the brass is once fired make sure is cleaned, resized and specially remove any burrs or extrusion marks from the base of the brass before resizing by using a fine file or sandpaper. any extrusion where

the plunger might have put a "bite" on the brass might create a ridge that doesn't make the whole face of the brass smooth. also marks in the rim

form the extractor. So in this case the first thing would be just to sand it so slightly and even the edge of the rim if there are any extractor bites.

Same if we want to trim the brass a bit to make it uniform at the mouth.

So after we have a perfectly smooth and bright and full sized brass (a couple of them will be fine. )

B) we can introduce the brass into the chamber that should just drop in. (plunk test).

C) We introduce the bolt as designed and rotate the bolt to go into battery. with our two finger there should not be any resistance of any kind.

notice that the bolt must be closed and pushed back (in this case pulled) that is the same effect the pressure from firing a round has to make

sure all lugs are in contact with the lugs as the bolt is pushed back into the battery position.

D) WE can rotate the bolt back and open and if we tap the inserted round it should drop right off. if not it can be gently pushed from the muzzle with a dowel or cleaning rod w/o damaging the crown or anything.

One could repeat this process with other cases including cases from our favorite manufacturer after pulling the bullet and empty the powder. I am not going to suggest to use a live round even there is no firing pin or anything that could cause a problem but everyone needs to know what feels safe or not and what ammo one wants to test.

AT THIS POINT, AFTER A FEW CHECKS WE KNOW THE CHAMBER IS LARGE ENOUGH FOR RELOADS AND/OR STANDARD FACTORY AMMO BUT WE HAVE NOT COMPLETED ALL SAFETY CHECKS YET.

NEXT...

1) After we do the above we are going to take one of the cases and drop it again in the chamber.

2) With the help of a flashlight or good lighting in the room we are going to verify that the chamber covers the entire case with the exception

of the rim.

A well supported case has a chamber that covers the entire web and obviously leaves a space for the bolt and extractor to work.

In other words, while we are doing the headspace we should also check on the chamber length to make sure that is also safe.

The headspace in a 5.56 is measured from the shoulder to the base (a) in picture but we also want to make sure we have enough

of the web that is inside the chamber. making a tenon too short is not something you see often but I have seen a cheap AR barrel

from PSA wiht a short tenon mistake that was not safe and the cases will buldge at the web and even the shooter was lucky not to

have one fail but hey was having all sort of extraction problems.. (not having enough of (b) X in blue support in picture below)

SO AFTER THIS WE WILL KNOW THE CHAMBER IS SAFE HAVING A LONG ENOUGH BARREL TENON AND CHAMBER TO SUPPORT THE CASE.

But we are not done yet. Now we have to make sure the chamber is also NOT TOO LARGE for the brass.

A) Take one of the FL formed brass and cut a piece of aluminum tape that should be around 2-3 thousands in thickness. you can measure the tape or you could simply measure the case with the calipers, add the tape and then cut around with a razor to make it perfectly round and flat and the measure again with the calipers. After adding 2 or 3 pieces of tape and depending on the length of the original sized brass one might have added 4 to 6 thousands that is measurable with the calipers. difference between the original measure w/o any tape.

B) In every step added we drop the case inside the chamber and proceed as above. We might not go above a certain length difference from the

brass that chambered.

WE just have to make sure the space between the base of the case and the bolt is not excessive after chambering. red space in picture below.

In military rifles this is larger than a match rifle to account for differences in service brass from all over, debris, weather, wear, etc...

and while brass is safe to expand a tad we want to make sure it doesn't go beyond a given point.

C) We will add tape and cut around and repeat as needed.

Because rifles of the same calibers can have different actual chambers some a tad shorter and some a tad longer it doesn't mean anything but also why 5.56 might be on the loose side to be more forgiving and reliable...

So this means 223 might have up 6 thousands or even less, at some point THE BOLT SHOULD NOT ROTATE INTO BATTERY!!! If you have added 6 or 8 thousands (max extreme being 10 thousands from min) and still close that is too large of a chamber. Ideally you do not even get to 6 thousands before you feel the bolt not wanting to close. at 8 thousands it should not close at all.

2 gauges with 6 thousands tolerance between a go chamber and no go. This is what is the minimum safe

for 223 as seen above but also used for 5.56 in many civilian chamberings.

IMPORTANT

This is also a tad relative because if you are using 2 or 3 pieces of brass you might want to size them all the same or

perhaps get a factory one and then find out what the differences are between those before start by measuring the

cases but you cannot measure the case from the mouth so use a case gauge or a small pistol case to create a stop

at the shoulder and measure relative differences.

Ideally the a case 'comparator' is the best way same with bullets that should be compared relative to the datum.

AT THIS POINT YOU SHOULD KNOW IF THE CHAMBER IS NOT TOO LARGE AND THEREFORE SAFE TO USE.

CONSIDERATIONS:

Alternatively to the tape measure one might fill out a case with hot glue or epoxy and/or a plastic dowel so one could thread

the thread end of a cleaning rod. This doesn't have to be too strong but it has to be secured and w/o play.

One will have to insert the cleaning rod and then thread the case into it and then push the case with the rod inside the chamber.

They key is that this is a firm fit and there is no any play between the case and the rod when pulling and pulsing so slightly.

Then, after closing the bolt and holding the bolt back by pulling (lugs againsts lugs) one could measure the difference in headspace

with one case by holding the bolt closed and then moving the rod and case front to back and marking with a razor flush by the muzzle in the cleaning rod. The difference between pulling and pushing on the bolt with that case we will see two marks in the rod. you can put some tape

at the muzzle and see the razor cuts there as marks that should be no longer than 6 thousands ideally.

The difference between those two marks will be the tolerance. In a tight chamber one might feel zero movement when pushing and

pulling so slightly.

One could even fill the case with sugar after putting a spent primer and leave enough space to seat a solid copper bullet backwards

that could be drilled and tapped with the same thread from the cleaning rod add glue so it doesn't move. Not a free imrpovised gauge

but not too expensive or hard to make.

There are several other methods that could give a pretty accurate measure in order to determine the tolerances inside the chamber.

Needless to say, if one is not mechanically oriented or doesn't have skills and minimum understand of mechanical things, this might feel

a strange process and one will be better checking with a gunsmith or someone who understands head-spacing like people who swap

barrels in a savage rifle between seasons. With a savage one can make the headspace really tight for ones competitions and/or hunting

and headspace to zero tolerances with once reloads or favorite factory ammo. This might mean some ammo will feel sticky going in

or even will not chamber. And that is why in service rifles, sporting guns the barrel makers give a tad more headspace to be more reliable

with a wide range of ammo and conditions.

Here is an example of someone making a very short chamber using tape to give about 2thousands longer than the go gauge.

This is obviously a very tight chamber for match type of use.

Last edited:

Briwesk85

.40 S&W

Wow call me stupid. I didn’t even know this was a thing...

I built 3 ARs in the last few months not even hearing about this.

so when do you need to check for head space? The 3 I built are all milspec and are functioning fine.

I built 3 ARs in the last few months not even hearing about this.

so when do you need to check for head space? The 3 I built are all milspec and are functioning fine.

meketrefe

.450/400 Nitro Ex

Wow call me stupid. I didn’t even know this was a thing...

I built 3 ARs in the last few months not even hearing about this.

so when do you need to check for head space? The 3 I built are all milspec and are functioning fine.

The chances of a dangerous chambering job are pretty low but they do happen.

Normally is the compounding of several errors made by the barrel maker and since many times people buy barrels from one side and bolts

from another there is no guarantee the aggregation of both being in the loose side is not going to result in a less than desirable headspace

even, if it is safe at the time we start the service life of the barrel.

Also broken bolts are more an issue with the retailer super cheap deals batches and occasional mistakes but rarely lead to a dangerous failure and

no much we can do about bolts other than buying from quality parts of a brand who actually makes parts, good ones. Young manufacturing for example.

Bottom-line, the headspace/chamber should be checked before you fire the weapon and every time you get a new bolt. I would suggest some

people who are not mechanically oriented have this done by a professional or order the barrel and bolt already matched at the factory.

Also keep in mind that ARs and 5.56 is pretty forgiving and why it gives those 10 thousands tolerance as a maximum for 5.56 but if one is going

to reload this should be even a more important consideration to extend the life of the brass and the barrel and obviously to be safe.

If a barrel is chambered a tad larger than average and close to the limit, still might be safe but as the parts wear and strech and we want to push the service life of the rifle there is no telling on where this will be a few thousands rounds down the road.

So better know your chamber, know your ammo and know your firearms the best you can and be safe.

It is a good practice and general directive.

Last edited:

PutnamCharlie

6.5 Creedmoor

I bought a set when I swapped out the bcg on two of my uppers. Pretty cheap way to be sure your not going to get a face full of bad day.

Briwesk85

.40 S&W

This is great advice and something I wasn’t aware of. I’ll be sure to have my head space checked before the next time I fire any of these in the future.The changes of a dangerous chambering job are pretty low but they do happen.

Normally is the compounding of several errors made by the barrel maker and since many times people buy barrels from one side and bolts

from another there is no guarantee the aggregation of both being in the loose side is going to result in a less than desirable headspace

even if it is safe at the time we start the service life of the barrel.

Also broken bolts are more an issue with the retailer super cheap deals batches and occasional mistakes but rarely lead to a dangerous failure and

no much we can do about bolts other than buying from quality parts of a brand who actually makes parts, good ones. Young manufacturing for example.

Bottom-line, the headspace/chamber should be checked before you fire the weapon and every time you get a new bolt. I would suggest some

people who are not mechanically oriented have this done by a professional or order the barrel and bolt already matched at the factory.

Also keep in mind that ARs and 5.56 is pretty forgiving and why it gives those 10 thousands tolerance as a maximum for 5.56 but if one is going

to reload this should be even a more important consideration to extend the life of the brass and the barrel and obviously to be safe.

If a barrel is chambered a tad larger than average and close to the limit, still might be safe but as the parts wear and strech and we want to push the service life of the rifle there is no telling on where this will be a few thousands rounds down the road.

So better know your chamber, know your ammo and know your firearms the best you can and be safe.

It is a good practice and general directive.

I have one that I’m concerned about as that is one I built from the ground up with all stripped parts, and barrel came from one place, bolt came from another.

The other two were prebuilt uppers with a BCG, so I think those should be ok, but it’s probably still worth checking.

Check this guy's channel out, really fascinating info on the details of tge AR15, gauging in particular.

Turns out the AR15 isn't quite Legos after all.

Turns out the AR15 isn't quite Legos after all.

Check this guy's channel out, really fascinating info on the details of tge AR15, gauging in particular.

Turns out the AR15 isn't quite Legos after all.

Buddy of mine is working on getting into one of his classes next year

Someday I would like to get the components together for a precision AR build and I'd like to put it together in his class. Then I can know it was put together properly, with the greatest possible precision and care.Buddy of mine is working on getting into one of his classes next year

Someday I would like to get the components together for a precision AR build and I'd like to put it together in his class. Then I can know it was put together properly, with the greatest possible precision and care.

It's funny how people don't understand how much can actually go into buildings a quality AR and how much of a difference it can make.... MiLsPeC is MiLsPeC

Last edited: