You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

UPDATE WITH BOYD"S STOCK - ADVICE NEEDED!! Anyone Have Experience With Boyd's Stocks?

- Thread starter prambo

- Start date

I bought one a couple of months ago for a Marlin 17HMR. Its Nutmeg color. It fit good and looks beautiful. Had no trouble ordering it. Buddy also bought one for his Savage 17wsm. He had no problems with the order but did have to glass bed the stock to acquire better accuracy. His stock is pepper,,,it was also beautiful.

For fun, Boyd's on an SCR. Does talk about the install, starting at about 1:11.

thegatman

.308 Win

I have had good luck with Boyd's stocks. Had one for a Marlin Camp 9 . Some fitting required for perfect fit. No complaints.

I have had good luck with Boyd's stocks. Had one for a Marlin Camp 9 . Some fitting required for perfect fit. No complaints.

I'm so pissed I didn't buy that one when it was available. I want the pepper stock for mine.

I have replaced a few stocks with Boyd's they are fantastic and worth the money.

Product DetailI'm so pissed I didn't buy that one when it was available. I want the pepper stock for mine.

You can use the "Custom Options" to get one in something other than black. They also offer it in a thumbhole version.

I had a pepper featherweight thumbhole from them. I got the stock unfinished so I could enlarge the thumbhole (I needed more clearance paws), and made it a project. It came out very nicely, and was a very comfortable stock.

This one? Product DetailI'm so pissed I didn't buy that one when it was available. I want the pepper stock for mine.

I don't want the thumbhole. They used to have one that looked almost the same as the original but in pepper.

Karpteach

6.5 Creedmoor

I own 3 and they are great.

The one I linked to isn't a thumbhole:I don't want the thumbhole. They used to have one that looked almost the same as the original but in pepper.

The one I linked to isn't a thumbhole:

The "Pro Varmint" - that's the one I'm going to order. It comes in black texture paint as the "no extra cost" finish.

Is the "pepper" or "forest camo laminate" worth the $15 for the upgrade? I'm tending toward the "forest camo" since I'm going to drop over $200 on it anyway by adding the Pachmayr recoil pad and the adjustable comb.

The one I linked to isn't a thumbhole:

Thanks, but the one they used to have that I want is identical to the Camp 9 stock but came in pepper. I should have bought it whe they had it.

Call them up, if they have the action pattern, I'm sure they will run what ever style you want. I'd be calling, but I don't have the cash to get it right now.Thanks, but the one they used to have that I want is identical to the Camp 9 stock but came in pepper. I should have bought it whe they had it.

The laminate colors look cooler, and since it's the actual wood, it won't chip like a coating could. I think it's worth it just for style points, but that's just me.The "Pro Varmint" - that's the one I'm going to order. It comes in black texture paint as the "no extra cost" finish.

Is the "pepper" or "forest camo laminate" worth the $15 for the upgrade? I'm tending toward the "forest camo" since I'm going to drop over $200 on it anyway by adding the Pachmayr recoil pad and the adjustable comb.

nortatoga

.338 Win Mag

Thanks, but the one they used to have that I want is identical to the Camp 9 stock but came in pepper. I should have bought it whe they had it.

I would give them a call, who knows what they may have in inventory that is not on the website?

Snappo

6.5 Creedmoor

Looking at them since they are the only place having exactly what I need.

Any input? Thanks!

I have a few. Minor sanding at worst. Quality group - no complaints on their products. The solids and the laminates are equally beautiful.

Snappo

6.5 Creedmoor

Thanks, but the one they used to have that I want is identical to the Camp 9 stock but came in pepper. I should have bought it whe they had it.

It's all blanks, software, and CNC. Call and they will probably make anything for you they ever ran runs of in the past.

It wont or shouldn't improve accuracy unless you glass bed it.Well, received stock, a few mods to the mag catch to increase threads into front lug and operate properly with mags.

Off to the range to see if it has improved accuracy.

Last edited:

It wont or shouldn't improve accuracy and less you glass bed it.

I'll show some groups and post the results later, but you are most likely correct. It's a little "wonkie", as it were.

Ok, so here is the rifle and today's targets.

It's a Ruger American in 30/06. Has a Nikon Buckmasters 4.5-14X scope (mil-dot, side focus, 1" tube). Scope mount is DNZ Game Reaper 1-piece mount that is a perfect fit. All screws have blue Loc-Tite. (Just looked at their site and they said do NOT use Loc-Tite because of the high thread count and length of the screws - thus, I might be "screwed" if I have to remove the scope). The stock is a Boyd's "Pro Varmint" in black finish with a Pachmyr recoil pad and adjustable comb.

Problems with fitting the stock were small. The front recoil lug screw wasn't getting enough threads into the action, IMHO, so I relieved part of the mag catch (through which the front lug screw passes and screws down on) so the screw turned more into the action. Had to remove a little wood and reshape the mag catch to get solid mag mounting - without reshaping, the mag would insert, but couldn't get it out. Both mags now insert aesily, do not move, feed perfectly, and remove easily enough. Here are some pics:

Now, for accuracy. With the original stock, a very, well, cheap plastic stock, there was alot of flex - only the unique Ruger V-block recoil lugs are metal. Almost regardless of ammo, the rifle, in original configuration, would place the first 2 shots touching or very close, and then throw the 3rd high and wide (5"+). Thus the Boyd's stock. The Boyd's stock results in a completely free-floated barrel, with contact betweeen the stock and barrel sarting at the muzzle end of the obvious barrel nut.

So today I took a variety of ammo to the range and tried it out. Here are the targets with running commentary between targets. The forend was on a sand filled V-bag and the rear was a slanted leather sand-filled bag. The rear of the rifle was controlled by resting my grip hand on the rear bag. Elevation was controlled by moving the front bag until the reticle ws below the aiming point and then pushing down on the rear bag to bring the reticle up prior to the shot. No pressure was put on the front of the rifle. The trigger pull was unmeasured, but left at the factory setting which is about 4 pounds. It can be adjusted down to 3 pounds.

All shots were followed by at least 1-2 minutes of cooling before the next shot. I'm not going to give ammo type for the first 2 targets as there was a possible reason they were such poor groups:

Thought the wood stock, laminated or not, I thought it might have "loosened" up a bit after this target, and sure enough, I was able to tighten the action screws up a good bit.

Once again, the action screws could be tightened up more after this group was shot. 5 rounds of commercially reloaded "M2" .MIL ammo, made from de-mil'ed components was fired in to the berm to seat the rifle and recoil lugs into the stock if necessary. The screws could be tightend about 1/8 of a turn more, and after this, the screws remained tight.

Next 2 3-round groups were shot with Remington 165 gr Core-Lok ammo (not bench grade obviously).

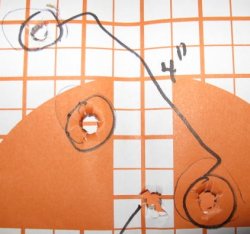

The shots are numbered in order of fire - 1 and 2 were touching, while shot 3 was thrown 2+3/8" inch high and left. Shot 4 touched shot 3, while shot 5 flew 2+3/4" high and right. The last shot, #6, was slightly to the left. The 4 groupm size was 1+1/16", while shots 1, 2 an4 formed a 1/2" group.

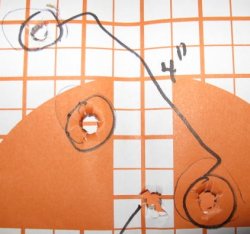

The last target was shot with 3 rounds Winchester Supreme factory loaded with Nosler 168 gr Ballistic Silvertip:

So, why are there flyers? As JamieZ pointed out above, it most likely needs to be glass-bedded. I have a new Brownell's Acra-Glas Gell kit to use. Only the lugs and lug areas will be glass bedded - the rear of the action is "free-floated" since there are no action screws mounted into it - bedding this area would be hard because the rear-mounted safety mechanism is "naked" and the parts are not enclosed. As can be seen in the rifle pics, the stock contacts the action and barrel in the area where they are joined. These areas could be relieved and glass bedded. The action around the trigger group could be bedded, but removing the trigger group is problematic - it is not mounted to the receiver with screws, but rather is pinned in place with

What are the reasons for the flyers?: the six shot group with Remington 165 gr Core-Lok shows the rifle is capable of very good accuracy for an inexpensive rifle - but why are there flyers after which shots return to the larger group?

1) - the rifle sucks regardless

2) needs to be glass bedded - bed just the lug/stock and lug/action areas, or also the action/barrel junction after relieving th stock?

3) the scope is screwed-up. It was originally mounted on a K31 which had shown sub-MOA accuracy out to 300 yards with another cheaper scope, but started to throw flyers after the Nikon was mounted - this seems to be the most possible explanation to me and, thus my concern about the thread locker "welding" the mount together.

Any opinions or insights into possible cures would be most welcome.

It's a Ruger American in 30/06. Has a Nikon Buckmasters 4.5-14X scope (mil-dot, side focus, 1" tube). Scope mount is DNZ Game Reaper 1-piece mount that is a perfect fit. All screws have blue Loc-Tite. (Just looked at their site and they said do NOT use Loc-Tite because of the high thread count and length of the screws - thus, I might be "screwed" if I have to remove the scope). The stock is a Boyd's "Pro Varmint" in black finish with a Pachmyr recoil pad and adjustable comb.

Problems with fitting the stock were small. The front recoil lug screw wasn't getting enough threads into the action, IMHO, so I relieved part of the mag catch (through which the front lug screw passes and screws down on) so the screw turned more into the action. Had to remove a little wood and reshape the mag catch to get solid mag mounting - without reshaping, the mag would insert, but couldn't get it out. Both mags now insert aesily, do not move, feed perfectly, and remove easily enough. Here are some pics:

Now, for accuracy. With the original stock, a very, well, cheap plastic stock, there was alot of flex - only the unique Ruger V-block recoil lugs are metal. Almost regardless of ammo, the rifle, in original configuration, would place the first 2 shots touching or very close, and then throw the 3rd high and wide (5"+). Thus the Boyd's stock. The Boyd's stock results in a completely free-floated barrel, with contact betweeen the stock and barrel sarting at the muzzle end of the obvious barrel nut.

So today I took a variety of ammo to the range and tried it out. Here are the targets with running commentary between targets. The forend was on a sand filled V-bag and the rear was a slanted leather sand-filled bag. The rear of the rifle was controlled by resting my grip hand on the rear bag. Elevation was controlled by moving the front bag until the reticle ws below the aiming point and then pushing down on the rear bag to bring the reticle up prior to the shot. No pressure was put on the front of the rifle. The trigger pull was unmeasured, but left at the factory setting which is about 4 pounds. It can be adjusted down to 3 pounds.

All shots were followed by at least 1-2 minutes of cooling before the next shot. I'm not going to give ammo type for the first 2 targets as there was a possible reason they were such poor groups:

Thought the wood stock, laminated or not, I thought it might have "loosened" up a bit after this target, and sure enough, I was able to tighten the action screws up a good bit.

Once again, the action screws could be tightened up more after this group was shot. 5 rounds of commercially reloaded "M2" .MIL ammo, made from de-mil'ed components was fired in to the berm to seat the rifle and recoil lugs into the stock if necessary. The screws could be tightend about 1/8 of a turn more, and after this, the screws remained tight.

Next 2 3-round groups were shot with Remington 165 gr Core-Lok ammo (not bench grade obviously).

The shots are numbered in order of fire - 1 and 2 were touching, while shot 3 was thrown 2+3/8" inch high and left. Shot 4 touched shot 3, while shot 5 flew 2+3/4" high and right. The last shot, #6, was slightly to the left. The 4 groupm size was 1+1/16", while shots 1, 2 an4 formed a 1/2" group.

The last target was shot with 3 rounds Winchester Supreme factory loaded with Nosler 168 gr Ballistic Silvertip:

So, why are there flyers? As JamieZ pointed out above, it most likely needs to be glass-bedded. I have a new Brownell's Acra-Glas Gell kit to use. Only the lugs and lug areas will be glass bedded - the rear of the action is "free-floated" since there are no action screws mounted into it - bedding this area would be hard because the rear-mounted safety mechanism is "naked" and the parts are not enclosed. As can be seen in the rifle pics, the stock contacts the action and barrel in the area where they are joined. These areas could be relieved and glass bedded. The action around the trigger group could be bedded, but removing the trigger group is problematic - it is not mounted to the receiver with screws, but rather is pinned in place with

What are the reasons for the flyers?: the six shot group with Remington 165 gr Core-Lok shows the rifle is capable of very good accuracy for an inexpensive rifle - but why are there flyers after which shots return to the larger group?

1) - the rifle sucks regardless

2) needs to be glass bedded - bed just the lug/stock and lug/action areas, or also the action/barrel junction after relieving th stock?

3) the scope is screwed-up. It was originally mounted on a K31 which had shown sub-MOA accuracy out to 300 yards with another cheaper scope, but started to throw flyers after the Nikon was mounted - this seems to be the most possible explanation to me and, thus my concern about the thread locker "welding" the mount together.

Any opinions or insights into possible cures would be most welcome.

meketrefe

.450/400 Nitro Ex

The groups are not unexpected for a budget gun with commercial off the shelve ammo.

However those budget stocks need some serious work and bedding job to work well.

These are things I would do:

-Bed the action including new pillars that make even contact and with no stress bedding job.

-Do not bed the shank area like some people do.

-See if the stock needs a steel insert to add rigidity and to avoid warping with weather changes typical of budget laminate and other wood stocks.

-Also bed the scope base with no stress bedding.

-Make sure the rings are also up to the task and see if they need lapping if they are not true.

-Eventually you will need a laser and plum to level the scope but torque to specs and if the scope doesn't hold zero you should find out in no time.

-After the bedding when you torque the screws make sure there is full contact with the pillars and the amount of thread is the appropriate otherwise

you might need to mill out enough material from the bottom for the right amount of thread engagement.

-Alternatively you could find some quality screws in the ACE hardware store that give the proper length. If the bottom of the magazine is plastic you

need to mill out all the plastic and insert a brass or aluminum bushing and epoxy that to the plastic piece. You want a metal to metal contact all the way yet enough tension to secure the bottom piece.

- Write down your torque settings as you will be adjusting these if needed. this has an impact in the harmonics of the barreled action.

-Find out your chamber COAL for the shot bullets to see how much headspace and freebore you have. This will give you an idea how far you are when testing

ammunition for specific bullet brand and type. you can check the amount of headspace by comparing the fired brass to the unfired brass for each batch.

- I guess the only alternative to adjust a load would be to reload for that chamber but I would try some match ammo first like federal gold match wiht 168gr Sierra Match King.

- Commercial chambers in budget rifles tend to be on the large size for liability reasons so do not be surprised you need to tune up your loads and end up

reloading to see groups closing up but any of the above measures will be a welcome improvement.

- If you are not going to use this rifle for hunting or you do not care a bit of extra weight you could also drill the back of the stock to add some

dead blow weight that always helps driving the rifle.

I hope this helps, at least some of it. Good luck.

Edit: I forgot. The nice thing about these new rifles that follow the savage directives is that you can get the barrel wrench and change head-space if you want. you will not be able to change the freebor (obviously) but you could adjust the head-space precisely to the brass that comes out of your dies or commercial ammo of your choice. I forgot to ask, what is your goal precision shooting or just a tad more consistency for hunting or fun?

However those budget stocks need some serious work and bedding job to work well.

These are things I would do:

-Bed the action including new pillars that make even contact and with no stress bedding job.

-Do not bed the shank area like some people do.

-See if the stock needs a steel insert to add rigidity and to avoid warping with weather changes typical of budget laminate and other wood stocks.

-Also bed the scope base with no stress bedding.

-Make sure the rings are also up to the task and see if they need lapping if they are not true.

-Eventually you will need a laser and plum to level the scope but torque to specs and if the scope doesn't hold zero you should find out in no time.

-After the bedding when you torque the screws make sure there is full contact with the pillars and the amount of thread is the appropriate otherwise

you might need to mill out enough material from the bottom for the right amount of thread engagement.

-Alternatively you could find some quality screws in the ACE hardware store that give the proper length. If the bottom of the magazine is plastic you

need to mill out all the plastic and insert a brass or aluminum bushing and epoxy that to the plastic piece. You want a metal to metal contact all the way yet enough tension to secure the bottom piece.

- Write down your torque settings as you will be adjusting these if needed. this has an impact in the harmonics of the barreled action.

-Find out your chamber COAL for the shot bullets to see how much headspace and freebore you have. This will give you an idea how far you are when testing

ammunition for specific bullet brand and type. you can check the amount of headspace by comparing the fired brass to the unfired brass for each batch.

- I guess the only alternative to adjust a load would be to reload for that chamber but I would try some match ammo first like federal gold match wiht 168gr Sierra Match King.

- Commercial chambers in budget rifles tend to be on the large size for liability reasons so do not be surprised you need to tune up your loads and end up

reloading to see groups closing up but any of the above measures will be a welcome improvement.

- If you are not going to use this rifle for hunting or you do not care a bit of extra weight you could also drill the back of the stock to add some

dead blow weight that always helps driving the rifle.

I hope this helps, at least some of it. Good luck.

Edit: I forgot. The nice thing about these new rifles that follow the savage directives is that you can get the barrel wrench and change head-space if you want. you will not be able to change the freebor (obviously) but you could adjust the head-space precisely to the brass that comes out of your dies or commercial ammo of your choice. I forgot to ask, what is your goal precision shooting or just a tad more consistency for hunting or fun?

Last edited:

The groups are not unexpected for a budget gun with commercial off the shelve ammo.

However those budget stocks need some serious work and bedding job to work well.

These are things I would do:

-Bed the action including new pillars that make even contact and with no stress bedding job.

-Do not bed the shank area like some people do.

-See if the stock needs a steel insert to add rigidity and to avoid warping with weather changes typical of budget laminate and other wood stocks.

-Also bed the scope base with no stress bedding.

-Make sure the rings are also up to the task and see if they need lapping if they are not true.

-Eventually you will need a laser and plum to level the scope but torque to specs and if the scope doesn't hold zero you should find out in no time.

-After the bedding when you torque the screws make sure there is full contact with the pillars and the amount of thread is the appropriate otherwise

you might need to mill out enough material from the bottom for the right amount of thread engagement.

-Alternatively you could find some quality screws in the ACE hardware store that give the proper length. If the bottom of the magazine is plastic you

need to mill out all the plastic and insert a brass or aluminum bushing and epoxy that to the plastic piece. You want a metal to metal contact all the way yet enough tension to secure the bottom piece.

- Write down your torque settings as you will be adjusting these if needed. this has an impact in the harmonics of the barreled action.

-Find out your chamber COAL for the shot bullets to see how much headspace and freebore you have. This will give you an idea how far you are when testing

ammunition for specific bullet brand and type. you can check the amount of headspace by comparing the fired brass to the unfired brass for each batch.

- I guess the only alternative to adjust a load would be to reload for that chamber but I would try some match ammo first like federal gold match wiht 168gr Sierra Match King.

- Commercial chambers in budget rifles tend to be on the large size for liability reasons so do not be surprised you need to tune up your loads and end up

reloading to see groups closing up but any of the above measures will be a welcome improvement.

- If you are not going to use this rifle for hunting or you do not care a bit of extra weight you could also drill the back of the stock to add some

dead blow weight that always helps driving the rifle.

I hope this helps, at least some of it. Good luck.

Edit: I forgot. The nice thing about these new rifles that follow the savage directives is that you can get the barrel wrench and change head-space if you want. you will not be able to change the freebor (obviously) but you could adjust the head-space precisely to the brass that comes out of your dies or commercial ammo of your choice. I forgot to ask, what is your goal precision shooting or just a tad more consistency for hunting or fun?

Thanks!! Great advice. I'll look into most of it. The Ruger bedding system doesn't use pillars, or a recoil lug that inserts into a stock recess like some other rifles. Here is a pic of the Ruger system:

The metal V-blocks are fixed in the plastic stock and mate with machined cut-outs in the bottom of the receiver. The Boyd's stock supplies metal V-blocks that fit into recesses in the laminate stock. Boyds themselves recommend that these V-blocks be bedded. At a minimum I was going to bed the V-blocks into the stock and, simultaneously, glass bed the action to the areas around the V-blocks to give optimum contact.

The metal V-blocks are fixed in the plastic stock and mate with machined cut-outs in the bottom of the receiver. The Boyd's stock supplies metal V-blocks that fit into recesses in the laminate stock. Boyds themselves recommend that these V-blocks be bedded. At a minimum I was going to bed the V-blocks into the stock and, simultaneously, glass bed the action to the areas around the V-blocks to give optimum contact.The stock seems to be very robust and heavy, and I could notice no flexing. This doesn't mean there isn't any, and the unfinished nature of parts of the stock obscured by the action could lead to warping with the weather. I may seal all these areas with a thin coat of glass bedding mix. It weights at least twice what the original plastic stock weighed and the forearm is thicker than a sporter across the bottom, affording a grip, as well as weight and rigidity. The recoil was minimal - the Pachmyr recoil pad works well.

The magazine is a sore spot - other than the spring and cartridge feed lips, it is entirely plastic. There is no metal insert in the mag "well". From reviews I read, I'm fairly lucky that both the original and other one I bought feed and lock in place well. It is a 4-round mag that uses the revolving mag priciple like the 10/22.

Re: the DNZ scope mount - it is all CNC machined in the USA, and I can't get the thinnest of objects in between any area where the mount meets the action. It appears to be an extremely close fit, plus is one piece (mounting area plus lower scope ring) so as to strengthen and reduce flexing of the action. That's why I chose it. As an aside, I CAN loosen the upper rings screws - wheeeww!! -I never use a lot of blue Loc-tite, just a very thin film - lucked out. But bedding it wouldn't be a real problem.

Once again thanks for the input - can't believe that the first, and only, bolt gun I ever bedded was a '03 Springfield, and I did that in about 1964-65 when I was about 16-17 years old - amazed I didn't glue the whole thing together. It was a real shooter (double-heat treated steel action, rebarreled in 1942 with a 4-groove target barrel at Springfield Armory) - sub-MOA groups with reloads off a gonzo rest and Lyman 48 peep sights. Don't even know where it is now - gave it away years ago before I went to Kenya.

meketrefe

.450/400 Nitro Ex

I am aware. Same thing whatever the lug design they need to be bedded and from the base of the screw all the way to the action it needs to be metal

in any contact points. Make sure you use a no stress system with bungies but you have enough tension to make the lugs stick well to the action.

For the plastic bottom the solution is easy but you need to find bushings drill out the base and then epoxy so those bushings match the original plastic profile

but now there will be making contact with the pillars going into the v blocks in this case.

Bodys provides a well priced stock but they don't do provide a full block because that would increase the cost and many people do not worry about seeking

maximum consistency anyway.

Keep in mind there are always going to be limitations from a budget commercial rifle. Sometimes people can invest a lot on them and still will not get what you get from a professional job. But at the other hand there are simple things that one can do and still keep it in a decent budget. Those things is properly done will not hurt. One can always rebarrel at some point.

in any contact points. Make sure you use a no stress system with bungies but you have enough tension to make the lugs stick well to the action.

For the plastic bottom the solution is easy but you need to find bushings drill out the base and then epoxy so those bushings match the original plastic profile

but now there will be making contact with the pillars going into the v blocks in this case.

Bodys provides a well priced stock but they don't do provide a full block because that would increase the cost and many people do not worry about seeking

maximum consistency anyway.

Keep in mind there are always going to be limitations from a budget commercial rifle. Sometimes people can invest a lot on them and still will not get what you get from a professional job. But at the other hand there are simple things that one can do and still keep it in a decent budget. Those things is properly done will not hurt. One can always rebarrel at some point.

I am aware. Same thing whatever the lug design they need to be bedded and from the base of the screw all the way to the action it needs to be metal

in any contact points. Make sure you use a no stress system with bungies but you have enough tension to make the lugs stick well to the action.

For the plastic bottom the solution is easy but you need to find bushings drill out the base and then epoxy so those bushings match the original plastic profile

but now there will be making contact with the pillars going into the v blocks in this case.

Bodys provides a well priced stock but they don't do provide a full block because that would increase the cost and many people do not worry about seeking

maximum consistency anyway.

Keep in mind there are always going to be limitations from a budget commercial rifle. Sometimes people can invest a lot on them and still will not get what you get from a professional job. But at the other hand there are simple things that one can do and still keep it in a decent budget. Those things is properly done will not hurt. One can always rebarrel at some point.

That's really the crux of the matter. And I honestly would be satisfied with consistent 100 meter groups of 2 MOA or less. It's the flyers that I want to eliminate. Your suggestions are going to go along way to doing that.

Ruger spent most of their costs on the American on the receiver/bolt/barrel. The plastic stock is rubbish. That being said, the barrel has a very thin profile - similar to a Win Mod. 70 "Featherwieght" I once had. By itself that will limit the inherent accuracy with heating up by shooting, regardless of the strength of the action. The barrel is "hammer-forged" but there certainly wasn't any metal "stress" relieving (cryo or otherwise) done on the barrel for an MSRP under $500 (and "street" price even less), although Ruger says the American "...offers minute of angle accuracy...".

The next step will be to bed the lugs and the receiver to the lug areas.

As far as the receiver area near the "receiver/barrel/barrel nut junction" goes, that area appears to closely contact the stock (you can see that in o2 of the pics in my big post above).

Would you suggest leaving the wood and bedding it, or relieving the wood and then bed that area? I'm leaning towards the latter, and bedding to end of the action/barrel nut area, and "free-floating" from there out.

Once again-thanks for your ideas and advice!!

meketrefe

.450/400 Nitro Ex

No need to say thanks. We all contribute and learn here at the same time, one way or another.

After you are done I will be surprised if you don't find a recipe closer to the 1 inch than the 2 inch groups at 100 yards.

The thing is we have a lot of relatively new budget rifles and everyone who wants to be competitive are following the Savage

directives but savage has been doing this for ever so they are quite far ahead in terms of consistency yet low manufacturing costs.

The stocks they all are Tupperware grade with some a tad better but they are done for cost effectiveness and nothing else.

Perhaps the worse plastic stock is the budget Remington 700 ADL and SPS yet the action is the most popular on the planet in terms

of a foundation for an accurate rifle with endless aftermarket support.

The American is a very nice action. I don't see anything wrong with the action to potentially become a good rifle but they

have not been consistent shooters like the axis. I think in part due to the barrels, chamberings and QC not being consistent.

So it is a hit and miss situation. One can get a very nice shooter and the next not up to the task. this is where Savage has proven to

be the leader in terms of consistency out of the box.

But you are not there yet IMO. Too early to determine. Need to do some work and test some other ammo.

I don't think the thinner profile of your barrel should be the determining factor. Only in prolonged and rapid strings of fire but there is

no reason why it should not produce consistent accuracy just based on the profile alone.

The hammer forged barrels might not the best method for extreme accurate rifles. Yes, they can produce very accurate barrels that is not

secret, but the most accurate barrels one can buy are either cut or button rifled. ie: Krieger, Lothar Walther, Scheneider, Rock, Bartlein,

Shilen / Bergara, etc...

I think this is where savage barrels get an edge. They have been able to produce a budget barrel superior to the competition. They are

just decades ahead in experience with this process w/o increasing the costs. The barrels are so good they are used in other rifles like

the Marlin XL7.

Regarding the lug area I would mill out as much as I can and then bed that area with the only difference that you will tape the nut

and barrel area so when you remove the tape this will actually float but the bed itself will add rigidity and help to avoid contact

if the wood warps with weather changes. All you have to leave is a high contact point but the rest you can remove as much as 1/4 of

an inch. It coudl be a great opportunity to insert a metal rod of hardened steel to help keep the wood in place. Might not be necessary

but while you are at it then why not right?

Make sure you put release agent in the outside of the electrical tape too in those areas so you don't end up locking everything up.

In summary I think you should see improvements. Later down the road you can decide if the barrel is something you want to change.

You can lap the barrel and I will tell you a couple of other tricks to play with the harmonics.

Or you can simply sell the new barrel in Ebay and get a match grade barrel and then follow that path. Either way the other work

that you do with the stock and action will give you huge benefits.

If you don't find a suitable bushing for the bottom piece but you tell me the thickness I will machine one for you with a shoulder so

it will be easier. But you shoudl be able to find one at the local ace store and after opening up the current holes you can epoxy and

then mill the excess metal after it is all cured.

Edit: I was thinking... if you have a drill press you could buy a larger bolt, cut two pieces, bore the middle and the rest will work as a bushing. Or buy a thread adapter and drill through the inside threads. Still epoxy the outside threads to the plastic bottom. you get the idea right? when the action screw comes there is nothing but even metal to metal contact all the way from the head fo the action screw to the action.

After you are done I will be surprised if you don't find a recipe closer to the 1 inch than the 2 inch groups at 100 yards.

The thing is we have a lot of relatively new budget rifles and everyone who wants to be competitive are following the Savage

directives but savage has been doing this for ever so they are quite far ahead in terms of consistency yet low manufacturing costs.

The stocks they all are Tupperware grade with some a tad better but they are done for cost effectiveness and nothing else.

Perhaps the worse plastic stock is the budget Remington 700 ADL and SPS yet the action is the most popular on the planet in terms

of a foundation for an accurate rifle with endless aftermarket support.

The American is a very nice action. I don't see anything wrong with the action to potentially become a good rifle but they

have not been consistent shooters like the axis. I think in part due to the barrels, chamberings and QC not being consistent.

So it is a hit and miss situation. One can get a very nice shooter and the next not up to the task. this is where Savage has proven to

be the leader in terms of consistency out of the box.

But you are not there yet IMO. Too early to determine. Need to do some work and test some other ammo.

I don't think the thinner profile of your barrel should be the determining factor. Only in prolonged and rapid strings of fire but there is

no reason why it should not produce consistent accuracy just based on the profile alone.

The hammer forged barrels might not the best method for extreme accurate rifles. Yes, they can produce very accurate barrels that is not

secret, but the most accurate barrels one can buy are either cut or button rifled. ie: Krieger, Lothar Walther, Scheneider, Rock, Bartlein,

Shilen / Bergara, etc...

I think this is where savage barrels get an edge. They have been able to produce a budget barrel superior to the competition. They are

just decades ahead in experience with this process w/o increasing the costs. The barrels are so good they are used in other rifles like

the Marlin XL7.

Regarding the lug area I would mill out as much as I can and then bed that area with the only difference that you will tape the nut

and barrel area so when you remove the tape this will actually float but the bed itself will add rigidity and help to avoid contact

if the wood warps with weather changes. All you have to leave is a high contact point but the rest you can remove as much as 1/4 of

an inch. It coudl be a great opportunity to insert a metal rod of hardened steel to help keep the wood in place. Might not be necessary

but while you are at it then why not right?

Make sure you put release agent in the outside of the electrical tape too in those areas so you don't end up locking everything up.

In summary I think you should see improvements. Later down the road you can decide if the barrel is something you want to change.

You can lap the barrel and I will tell you a couple of other tricks to play with the harmonics.

Or you can simply sell the new barrel in Ebay and get a match grade barrel and then follow that path. Either way the other work

that you do with the stock and action will give you huge benefits.

If you don't find a suitable bushing for the bottom piece but you tell me the thickness I will machine one for you with a shoulder so

it will be easier. But you shoudl be able to find one at the local ace store and after opening up the current holes you can epoxy and

then mill the excess metal after it is all cured.

Edit: I was thinking... if you have a drill press you could buy a larger bolt, cut two pieces, bore the middle and the rest will work as a bushing. Or buy a thread adapter and drill through the inside threads. Still epoxy the outside threads to the plastic bottom. you get the idea right? when the action screw comes there is nothing but even metal to metal contact all the way from the head fo the action screw to the action.

Last edited:

Beginning to see a step-by-step plan that will not cost me the bomb ($$$ is limiting unfortunately), and yield consistent accuracy, regardless if it is sub-MOA or between 1-2 MOA. Being mostly a pistol/AR/AK/SKS kind of guy, wringing accuracy out of a bolt gun is not one of my fortes. The '03 Springfield I mentioned came to me with superior accuracy (back in the day, when you ordered it witha MO and received it by mail) - the glass bedding of the after-market stock was the final piece, so I had to know, and do, relatively little to get sub-MOA results.No need to say thanks. We all contribute and learn here at the same time, one way or another.

After you are done I will be surprised if you don't find a recipe closer to the 1 inch than the 2 inch groups at 100 yards.

The thing is we have a lot of relatively new budget rifles and everyone who wants to be competitive are following the Savage

directives but savage has been doing this for ever so they are quite far ahead in terms of consistency yet low manufacturing costs.

The stocks they all are Tupperware grade with some a tad better but they are done for cost effectiveness and nothing else.

Perhaps the worse plastic stock is the budget Remington 700 ADL and SPS yet the action is the most popular on the planet in terms

of a foundation for an accurate rifle with endless aftermarket support.

The American is a very nice action. I don't see anything wrong with the action to potentially become a good rifle but they

have not been consistent shooters like the axis. I think in part due to the barrels, chamberings and QC not being consistent.

So it is a hit and miss situation. One can get a very nice shooter and the next not up to the task. this is where Savage has proven to

be the leader in terms of consistency out of the box.

But you are not there yet IMO. Too early to determine. Need to do some work and test some other ammo.

I don't think the thinner profile of your barrel should be the determining factor. Only in prolonged and rapid strings of fire but there is

no reason why it should not produce consistent accuracy just based on the profile alone.

The hammer forged barrels might not the best method for extreme accurate rifles. Yes, they can produce very accurate barrels that is not

secret, but the most accurate barrels one can buy are either cut or button rifled. ie: Krieger, Lothar Walther, Scheneider, Rock, Bartlein,

Shilen / Bergara, etc...

I think this is where savage barrels get an edge. They have been able to produce a budget barrel superior to the competition. They are

just decades ahead in experience with this process w/o increasing the costs. The barrels are so good they are used in other rifles like

the Marlin XL7.

Regarding the lug area I would mill out as much as I can and then bed that area with the only difference that you will tape the nut

and barrel area so when you remove the tape this will actually float but the bed itself will add rigidity and help to avoid contact

if the wood warps with weather changes. All you have to leave is a high contact point but the rest you can remove as much as 1/4 of

an inch. It coudl be a great opportunity to insert a metal rod of hardened steel to help keep the wood in place. Might not be necessary

but while you are at it then why not right?

Make sure you put release agent in the outside of the electrical tape too in those areas so you don't end up locking everything up.

In summary I think you should see improvements. Later down the road you can decide if the barrel is something you want to change.

You can lap the barrel and I will tell you a couple of other tricks to play with the harmonics.

Or you can simply sell the new barrel in Ebay and get a match grade barrel and then follow that path. Either way the other work

that you do with the stock and action will give you huge benefits.

If you don't find a suitable bushing for the bottom piece but you tell me the thickness I will machine one for you with a shoulder so

it will be easier. But you shoudl be able to find one at the local ace store and after opening up the current holes you can epoxy and

then mill the excess metal after it is all cured.

Edit: I was thinking... if you have a drill press you could buy a larger bolt, cut two pieces, bore the middle and the rest will work as a bushing. Or buy a thread adapter and drill through the inside threads. Still epoxy the outside threads to the plastic bottom. you get the idea right? when the action screw comes there is nothing but even metal to metal contact all the way from the head fo the action screw to the action.

I'll keep this post going - your info and insights are very helpful.

meketrefe

.450/400 Nitro Ex

I think there is no plug and play or shortcut. The budget stocks are price attractive but they have obvious limitations. They would not

be able to offer the prices they offer if the stocks included more features and manufacturing.

One could buy a $500 stock and still have bedding work to do anyway so all we are doing here is to use alternative cost effective

methods to achieve the same starting with a good bedding compound and job. With these cheap stocks one will end up using extra

bedding compound but that means a couple of dollars more perhaps? So it is nothing.

Some people will tell you buy a $3000 rifle from a builder and be done but we know that is out fo budget for a lot of people or

simply not needed.

Some things are really simple and inexpensive so don't get discouraged. I was looking for some bedding videos for you and found

this guy that is doing a budget rifle for the average working man on a budget. I don't necessarily agree with everything he is

doing but it is not bad and a good set of ideas that resolve some of the Axis problems similar to what you have.

Watch the whole series as he deals inexpensively with the pillar bedding, cheap plastic magazine bottom, etc. Some things do not apply to the new axis II nor your Ruger Aerican anyway but you will get the philosophy of the whole DIY type of easy improvements we are talking about. Again take with a grain of salt and we can talk about some of the things he does how to do them a bit differently and possibly better but the idea is to get the general idea behind some of the accuracy directives that have been there for a long time.

be able to offer the prices they offer if the stocks included more features and manufacturing.

One could buy a $500 stock and still have bedding work to do anyway so all we are doing here is to use alternative cost effective

methods to achieve the same starting with a good bedding compound and job. With these cheap stocks one will end up using extra

bedding compound but that means a couple of dollars more perhaps? So it is nothing.

Some people will tell you buy a $3000 rifle from a builder and be done but we know that is out fo budget for a lot of people or

simply not needed.

Some things are really simple and inexpensive so don't get discouraged. I was looking for some bedding videos for you and found

this guy that is doing a budget rifle for the average working man on a budget. I don't necessarily agree with everything he is

doing but it is not bad and a good set of ideas that resolve some of the Axis problems similar to what you have.

Watch the whole series as he deals inexpensively with the pillar bedding, cheap plastic magazine bottom, etc. Some things do not apply to the new axis II nor your Ruger Aerican anyway but you will get the philosophy of the whole DIY type of easy improvements we are talking about. Again take with a grain of salt and we can talk about some of the things he does how to do them a bit differently and possibly better but the idea is to get the general idea behind some of the accuracy directives that have been there for a long time.