mgunner

.45 acp

I went down the reloading hole several years ago. Now I've decided to go down the bullet casting hole. Anybody else cast? I'll be getting a casting pot for Christmas. Any practical advice for a newbie?

I saw that forum but before I joined it I thought maybe someone here might be able to help.Join the Cast Boolits forum

Thanks for the information.I do. Never with wheel weights..just lead bars already hardened (Br.10-15). Use an electric molten pot. I use Lee 2 or 6 cavity molds..aluminum bodied with wood handles. I also use Lee bullet sizing dies after tumbling the bullets in Alox. After that they load nicely.

Lot of things to learn along the way. Never use the first bullets dropped from the molds..or the 2nd..maybe not even third. Drop em back into the melting pot. The molds need to heat up uniformally, or the bullets will have air pockets and be weak. When you do drop bullets, do so in a bucket of water. They will solidify faster. Some don't use the bullet resizers..I swear by them. Each bullet mold has the bullet type on it. Lee has a nice chart on their specs..what type, diameter, sizing die, to lube/not lube, to use/not use gas checks, etc. Cast boolits has the load data that people experiment with.

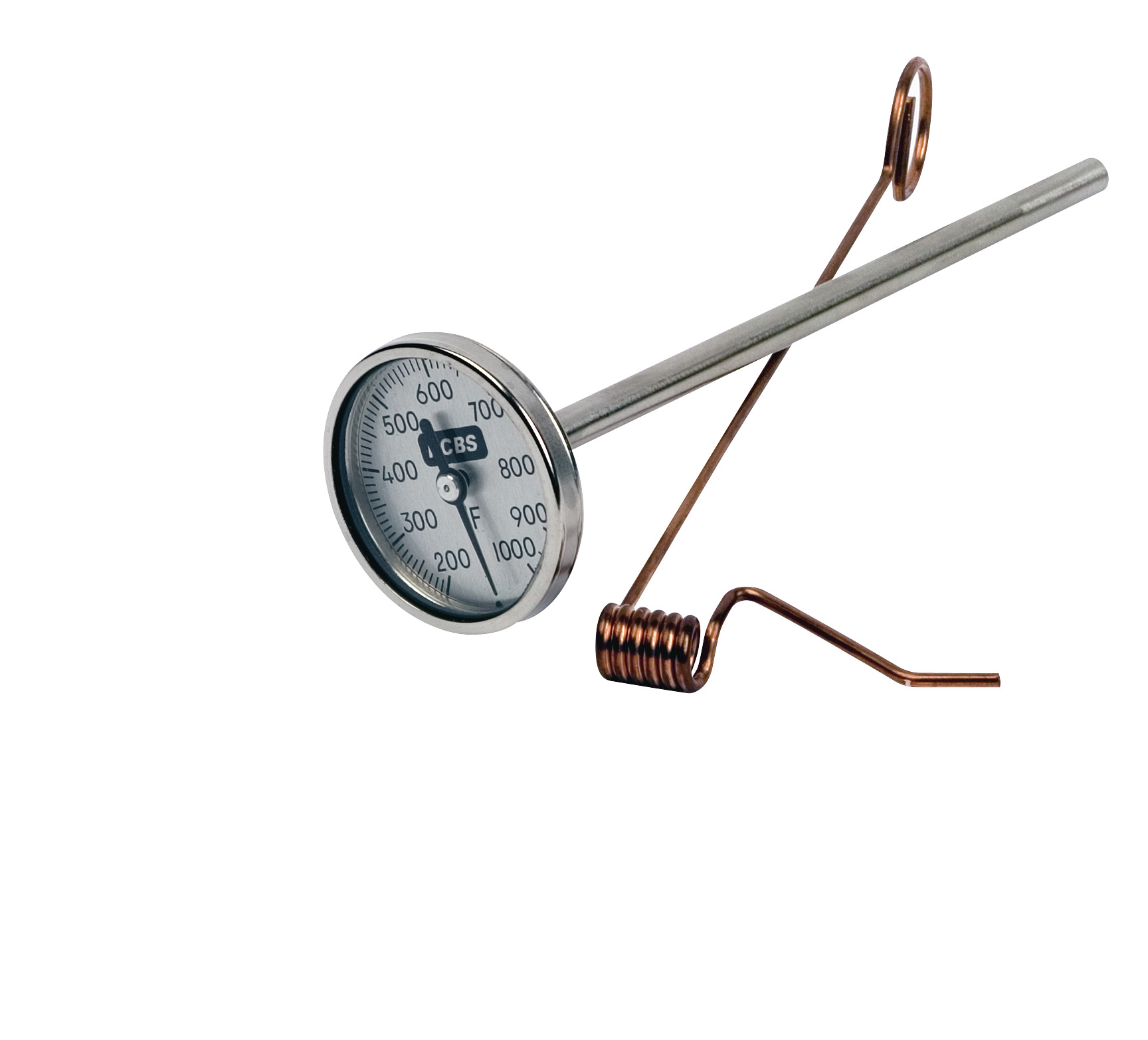

I'm also getting the Lyman Cast Bullet Handbook for Christmas. I'll have to buy myself a thermometer at some point. I was looking at the Lyman digital. Which one do you use?Perhaps buy the Lyman cast bullet handbook ~*$25

Save tin cans for the slag disposal.

Sawdust, bees wax, Can't think of the chemical added to keep the melt in flux.

Thermometer very important.

Lee smelter/drippers can be fixed with valve grinding powder,

Good set of thick leather (welding) gloves.

Boric acid

Why should I slug the barrel?Get some pure lead and slug the barrel of the guns you will cast for.

No problem. So one place I was getting ingots is right from Midway. Cheaperthandirt also.Thanks for the information.

I know Rotometals.com sells lead, is that where you buy it? If not, what other sources do you use?

Question about sizing the bullets. Do you size your bullets to SAAMI specs or do you case them .001 or .002 over your bore diameter?

Are you using the bullet sizing die to meet SAAMI specs or are you buying a Lee mold that oversaizes them when cast and then squeezing them down so they are .001 or .002 over you bore diameter?

Get some pure lead and slug the barrel of the guns you will cast for.

Why should I slug the barrel?

I watched several videos and learned about safety, types of clothes to wear, etc. Before I started to watch videos about bullet casting I knew that the best thing to do was to cast outside. Lead is poisonous when it's in it's solid state, so common sense told me right away that I don't want to breath any fumes in either. I'll also be wearing a mask rated for fumes. From what I've seen, a filter rated P100 is the proper one to wear.I cast a bit. Mostly just to know how to do it. Most of what I shoot, I buy.

Watch a bunch of youtube videos, then give it a try. Elvis Ammo has some good info.

Good ventilation and hygiene is a must. Lead poisoning will mess you up - I know from experience from exposure at a previous job. Open a window or do it outside, wash your hands when your done, and especially if you have kids be careful about secondary exposure (clothes, shoes, etc).

Glasses are a good idea. Long pants and long sleeves are a good idea. If you ever had melted solder drip on you, that's what melted lead feels like. A little bit on skin hurts but is bearable, a big spill will mess you up. if it drips on your pants leg, you see it but it doesn't hurt.

Make sure your lead is dry before it goes into a hot pot. Water in melted lead turns to steam and splashes like crazy.

After that, its trial and error. If you mess up, just throw them back in the pot and try again.

When I started, I was tumble-lubing with Alox. Now I use Hi-Tek coating. It works better for me and less messy.

If you have any specific questions, just ask.

I saw a video on YouTube from GunBlue490 about casting. I'm going to take his advice as well. As soon as I'm done casting I'm going to throw my clothes in the washing machine. I don't want to be sitting on furniture with lead dust on my clothes. And I'll wash my hands really well. May take a quick shower as well. I'm just going to be really careful.don't forget the snacks when melting lead and casting ..

I think the chips and dust is more hazardous then melting real lead ...

bring the melted lead to a boil then you got issues with lead gasses ..

its the impurities in the lead bar that your melting is what to be safe from ..

that's my opinion ..

i used to use my teeth to pull 22LR bullets from the case when i was a teenager lol

PS .. hell back then they filled your cavity with mercury ..

I still do some, I have a lot already cast up in various calibers so only cast about one or two days a year. I use mostly wheel weights followed by berm turds and finally new alloy's from Roto Metals. I use super hard from Roto Metals to harden up the berm turds, I used to have a Lee hardness tester until I loaned it out. Oh well, back to the xx pounds of WW and so much solder to make such n such, I shoot mostly Lyman#2 like recipes and size with a Lyman sizer/luber and install gas checks if needed. I do have some Lee sizers and use them, Alox not so much. Seems to be to damn messy and sticky! It does work great for .38 wadcutters! After loading I just wipe the face of the bullet with a rag and solvent, no more sticky mess.

I don't EVER get anything from cheaper than dirt! In my opinion they're back stabbing POS!

Midway is a bit pricey and shipping adds up.

I use a mix of differing molds from differ makers, some aluminum, steel, brass. The very best ones I have are NOE brass , once you use one of his molds you really won't want to go back to the LEE aluminum again! But $$ is a big factor starting out.

As for lead. Ask around wheel weights are real hard to come by now, but they are still out there. Battery terminals and clamps can be a source DO NOT USE BATTERY PLATES THEMSELVES!! Bad juju.

I used to always carry an empty cup going down range to change targets, while guys are walking back from the 100 yd line, I'd fill the cup with range turds at the 25yd line, free lead for just picking it up. DO NOT DIG UP THE BERMS!

Last year I gave 8 very full 5 gallon buckets of lead away ( to the same guy who borrowed my lead tester), sometimes you just realize you have to much.

I've seen pan lubing online. There are a several videos about it so I'll keep that in mind.I don't cast myself but have tried many cast bullets. I got a batch of Hi Teks that leaded the barrel of one of my revolvers horribly. I figured out they were too big and guessed that the coating was coming off as each bullet squeezed through the cylinder. I pan lubed the batch and that totally eliminated the leading.

Tumble lubing is easy, but pan lubing can give great results. I did it with a mix of generic petroleum jelly and bees' wax. I forget the ratio since I only mixed up one big jarful and still have some left, but it's out there somewhere. If tumble lubing doesn't work out great for you, pan lubing is a relatively easy backup plan to keep in the back pocket.

I asked one of the guys at my garage if they could ask the owner about wheel weights. I have to call them back to see what they say.

Good advice thank you. I saw a video about about zinc and steel wheel weights and how to tell them apart.its been i would say like 5 yrs now since i hit the car dealer here up for 5 gal pails of wheel weights ..

got 4 pails and there all a mix of lead and FE ( steel ) and Zinc weights ..

you might get 5 or 10 lbs out them these days if your lucky .. or nothing at all ..

i still have 2 pails to sort through ..

i would not pay anything for a pail of wheel weights these days .. just gladly to take them off your hands ..

PS .. un less I'm seeing actual lead weighs on the top layer of the pail ..

Good advice thank you. I saw a video about about zinc and steel wheel weights and how to tell them apart.