Deplorable Me

.700 Nitro Express

Amongst all my other prepper lighting resources (Coleman, candles and flashlights) I've also collected a few kerosene lanterns. Kerosene is for outside use, paraffin or synthetic kerosene can be cleanly burned inside. I've found a little goes a long ways. I use citronella and kerosene in my lanterns and it last a lot longer than burning it in Tiki torches to keep away summer bugs. Stable flame and a lot more light than Tikis. They hold up to the wind.

V&O lanterns are sub-quality, Dietz lanterns are the go-to brand. Around WNY I've picked up lanterns at the hardware store in Cherry Creek (Amish country.). Dietz originated in America but years ago production went to China . Still Dietz is the only good brand these days.

. Still Dietz is the only good brand these days.

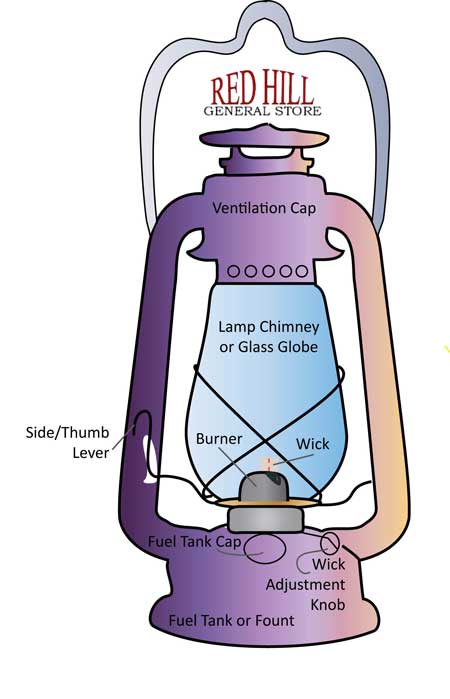

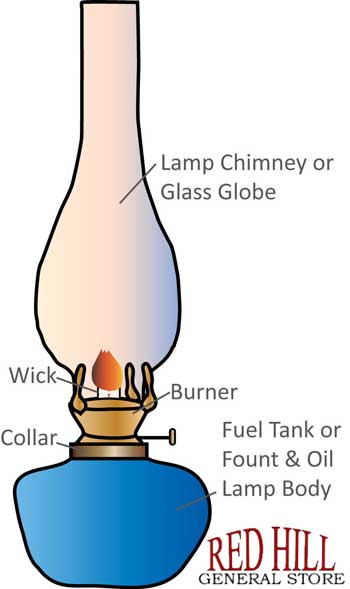

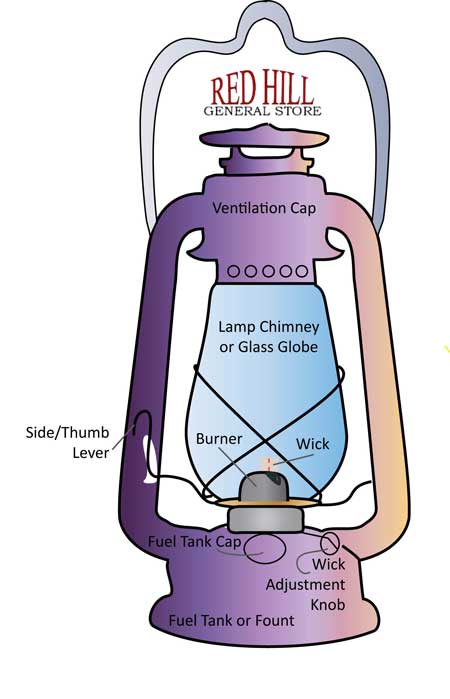

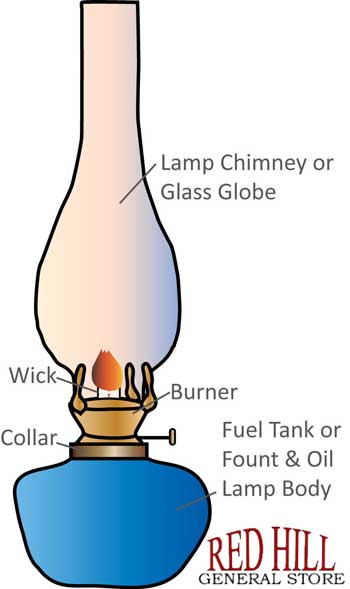

Parts of a kerosene lantern

Don't be stuck in a power outage relying on batteries! Here is a diagram of kerosene lantern parts:

Fundamentals of lantern construction

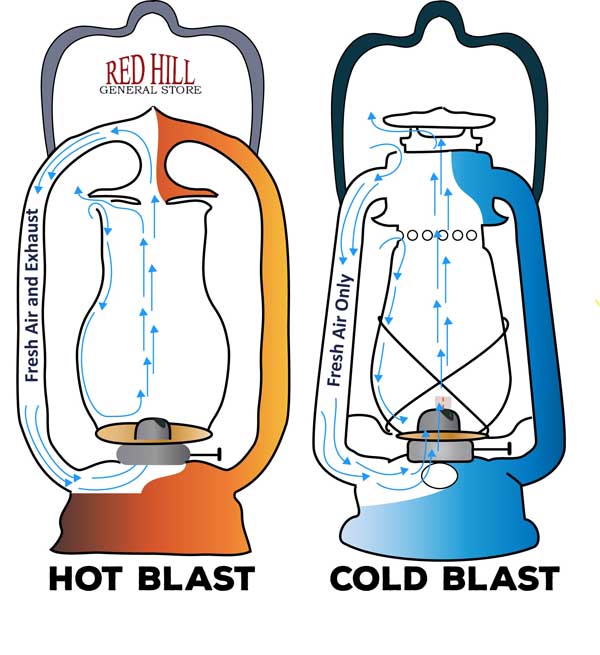

We want to help you safely use and operate oil lanterns so they are more than useless decorations. Flat wick lamps and lanterns are designed for portable use are made in three varieties: dead-flame, hot-blast and cold-blast.

Dead-Flame Lanterns

Dead-flame is the most simple type of kerosene lamp that burns fuel by drawing it up through a wick. If the lamp breaks the design can easily start fires. Dead-flame lamps have a fuel tank (fount) that attaches to a wick-holding lamp burner with four prongs to hold the glass chimney; enhancing the thermal draft and preventing the flame from being blown out. Airflow to the wick is controlled through burner vents and the open chimney. Creating a tight connection between the chimney and burner is known as making a "throat". This allows for complete combustion that carries more oxygen past the flame for a steady smoke-free light that's brighter than an open flame.

Both hot and cold blast lanterns are tubular designs; when they get knocked over oxygen is cut off to the burner and the flame is extinguished.

Hot-Blast

The hot-blast design was invented by John Irwin with a January 12, 1868 Patent. This design takes hot air from just above the globe and channels it through the side tubes to the flame where some of the spent air is recirculated through the tubes. The invention of hot-blast lamps allowed for a brighter and more stable flame.

Cold-Blast

The cold-blast design sucks in more fresh air from around the globe and lantern top and channels it through the side tubes to the flame where all of the spent air is released. With no air recycling and plenty of fresh oxygen to feed the flame, the cold-blast design achieved the most efficient process of combustion with the brightest and most stable flame.

What is a hurricane lantern?

According to the Merriam-Webster dictionary a hurricane lamp, "or hurricane lantern: an oil lantern having a glass chimney with a perforated metal lid that permits the egress of air but protects the flame from high winds and used usually on shipboard and to mark outdoor construction projects -called also tornado lantern"

A hurricane lamp can also be a deadflame lantern equipped with a hurricane globe. Or an electric lamp with a hurricane globe instead of a shade.

What type of fuel to use in old fashioned lanterns?

Standard lamp oil, Clear-Lite synthetic kerosene, or kerosene substitute are recommended for use indoors. Clear K-1 kerosene is recommended for outdoor use only. Read the full list of indoor and outdoor approved lantern fuels here.

How to fill an oil lantern with oil

See our list of approved lantern oils for use inside and outside. To fill an oil lantern, unscrew the fuel cap and pour in oil lamp oil. You can use a funnel if you're worried about spilling, some lanterns today even come packaged with one.

Fill lantern to 85% full for normal use. Only fill to 100% (the bottom level of the filler hole) when maximum burning time is required. Filling over 100% allows fuel to leak out of burner socket into the side air lantern tubes. Overfilled lanterns seep and the front weeps. If you overfill a lantern dump some fuel out to bring it back to the proper level then set it on some absorbent material so it can seep for a while.

Use room temperature oil to achieve a splendid burn. The chemical composition of lamp oil expands in high temperatures and freezes in temps below 20 degrees; preventing prime burning.

Once your lantern or lamp is full of oil allow the wick to saturate for 30 minutes. The wick is ready to light when it is darkened with oil.

Don't store a lantern with too much oil. Oil lamp fuel expands in warm temperatures and are known to overflow in the spring.

Once your lantern is full of oil, you're ready to light the wick for the first time.

Want to know how much lamp oil should you buy? Read our section on how much lamp oil you need.

How do you light a lantern?

How to put out an oil lantern

To put out a kerosene lamp turn the wick down into the burner until the flame goes out. Turning too far can cause the wick to become unthreaded from the burner assembly completely. Remember the globe is still hot! Wait until completely cool before touching globe.

Oil lantern operation tips

Storing lanterns

If you store your lantern outside in extreme temperatures, condensation will form inside the fuel front. The kerosene will float on top of the water and the inside bottom will rust. If you want to store lanterns outside in an unheated space dump the fuel out. If you store inside, dump the fuel every year or so to keep it relatively fresh. You can store lanterns in original containers or other cardboard boxes.

The differences of Dietz and V&O lanterns

How you want to use the lantern will help you decide which brand is best for you. V&O lanterns provide just as much light as their Dietz counterparts at a fraction of the cost. The metal to construct V&O lanterns is thinner. If you're going to be carrying the lantern around while camping or operating in spaces where it could get knocked around, you will be better off with the more expensive and durable Dietz lanterns. V&O lanterns will serve you well where impact damage is less likely. V&O oil lanterns are best in relatively stationary situations - hanging on a hook, carrying gently in the summer, or adding charm as table centerpieces.

Construction details of how Dietz and V&O lanterns are made are provided in the remaining text of this answer. Most oil lanterns are made with crimped tin-plated steel sheet metal. Hurricane oil lanterns or cold-blast lanterns can also be made with brass and copper.

Dietz lanterns are made with plates of thick tin-coated steel finished with a hard-wearing lacquered enamel color to prevent rust. Interior fuel tanks are plated to thwart rust. The durable lantern construction facilitates seamless operation; even in lawless weather conditions. The burners, like the fuel tank interior, is made with tin that doesn't rust and withstands a heated flame.

V&O lanterns work well and provide a lot of light. They do not leak kerosene like cheaper lanterns. V&O lanterns are made with thinner plates of tin-coated steel. An enamel color finish is also applied to prevent rust. Tanks and burners are too made to prevent rust. It has to be said: the general fit and overall quality of these lamps is less than Dietz. A little adjusting improves minor manufacturing discrepancies. You'll want to make sure all vent holes are unobstructed for optimum air flow; sometimes they are clogged in the manufacturing process. Also check to determine a tight globe to burner connection or "throat"; minor adjustments with pliers can make a better flame and brighter light.

Where are Dietz Lanterns made?

In 1956 the lantern division of the R.E. Dietz company moved to hong kong in 1956 and to China in 1982. Today the factory operates from Jiangsu, China after the last move in 2005, while the offices are still in Aberdeen, Hong Kong.

Dietz lanterns were made in the United States until 1956. When the Dietz factory moved to hong kong they no longer stamped patent and production information onto lanterns.

Lanterns made before 1956 were manufactured in Syracuse, N.Y and New York City. Find the "M" or "S" patent date located under the production date, usually stamped on the top part of the air tube on the right of the fuel cap or on the center air tube on hot-blast lanterns. See table two for what we can tell you about your lantern.

Where are V&O Lanterns made?

V&O Lanterns today are made in China. In 2005 the V&O company brand was bought by 21st century inc.

V&O lanterns are sub-quality, Dietz lanterns are the go-to brand. Around WNY I've picked up lanterns at the hardware store in Cherry Creek (Amish country.). Dietz originated in America but years ago production went to China

Oil Lanterns - Old Fashioned Lanterns | Red Hill General Store

Oil Lanterns are an old fashioned favorite. Largest selection of oil lantern sizes, colors and brand. Light the way in a storm. Quick shipping from Virginia.

www.redhillgeneralstore.com

Parts of a kerosene lantern

Don't be stuck in a power outage relying on batteries! Here is a diagram of kerosene lantern parts:

Fundamentals of lantern construction

We want to help you safely use and operate oil lanterns so they are more than useless decorations. Flat wick lamps and lanterns are designed for portable use are made in three varieties: dead-flame, hot-blast and cold-blast.

Dead-Flame Lanterns

Dead-flame is the most simple type of kerosene lamp that burns fuel by drawing it up through a wick. If the lamp breaks the design can easily start fires. Dead-flame lamps have a fuel tank (fount) that attaches to a wick-holding lamp burner with four prongs to hold the glass chimney; enhancing the thermal draft and preventing the flame from being blown out. Airflow to the wick is controlled through burner vents and the open chimney. Creating a tight connection between the chimney and burner is known as making a "throat". This allows for complete combustion that carries more oxygen past the flame for a steady smoke-free light that's brighter than an open flame.

Both hot and cold blast lanterns are tubular designs; when they get knocked over oxygen is cut off to the burner and the flame is extinguished.

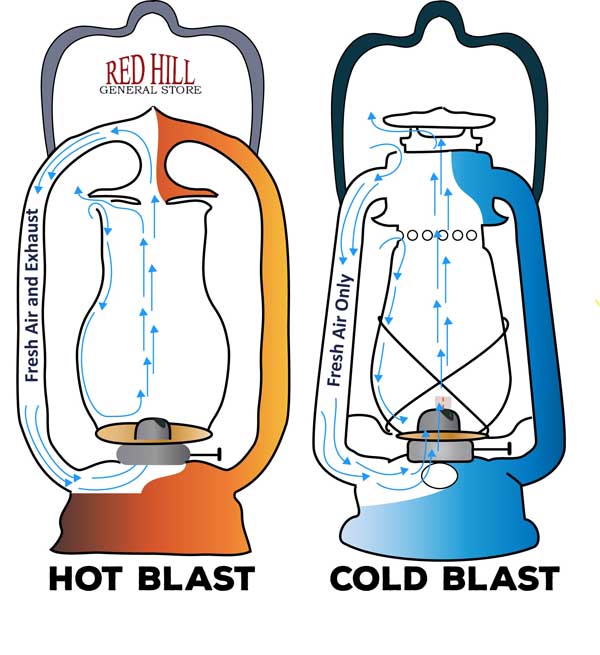

Hot-Blast

The hot-blast design was invented by John Irwin with a January 12, 1868 Patent. This design takes hot air from just above the globe and channels it through the side tubes to the flame where some of the spent air is recirculated through the tubes. The invention of hot-blast lamps allowed for a brighter and more stable flame.

Cold-Blast

The cold-blast design sucks in more fresh air from around the globe and lantern top and channels it through the side tubes to the flame where all of the spent air is released. With no air recycling and plenty of fresh oxygen to feed the flame, the cold-blast design achieved the most efficient process of combustion with the brightest and most stable flame.

What is a hurricane lantern?

According to the Merriam-Webster dictionary a hurricane lamp, "or hurricane lantern: an oil lantern having a glass chimney with a perforated metal lid that permits the egress of air but protects the flame from high winds and used usually on shipboard and to mark outdoor construction projects -called also tornado lantern"

A hurricane lamp can also be a deadflame lantern equipped with a hurricane globe. Or an electric lamp with a hurricane globe instead of a shade.

What type of fuel to use in old fashioned lanterns?

Standard lamp oil, Clear-Lite synthetic kerosene, or kerosene substitute are recommended for use indoors. Clear K-1 kerosene is recommended for outdoor use only. Read the full list of indoor and outdoor approved lantern fuels here.

How to fill an oil lantern with oil

See our list of approved lantern oils for use inside and outside. To fill an oil lantern, unscrew the fuel cap and pour in oil lamp oil. You can use a funnel if you're worried about spilling, some lanterns today even come packaged with one.

Fill lantern to 85% full for normal use. Only fill to 100% (the bottom level of the filler hole) when maximum burning time is required. Filling over 100% allows fuel to leak out of burner socket into the side air lantern tubes. Overfilled lanterns seep and the front weeps. If you overfill a lantern dump some fuel out to bring it back to the proper level then set it on some absorbent material so it can seep for a while.

Use room temperature oil to achieve a splendid burn. The chemical composition of lamp oil expands in high temperatures and freezes in temps below 20 degrees; preventing prime burning.

Once your lantern or lamp is full of oil allow the wick to saturate for 30 minutes. The wick is ready to light when it is darkened with oil.

Don't store a lantern with too much oil. Oil lamp fuel expands in warm temperatures and are known to overflow in the spring.

Once your lantern is full of oil, you're ready to light the wick for the first time.

Want to know how much lamp oil should you buy? Read our section on how much lamp oil you need.

How do you light a lantern?

- Push down thumb lever to raise the glass globe and expose the wick.

- Light the wick (as long as the tank is filled and wick has been saturated with oil)

- Return lever and globe to original position.

- The wick should be adjusted to 1/16" - 1/8" above the flame plate.

- As lantern warms up the flame will increase in size.

- Five minutes after lighting you may adjust the flame for maximum light. If the wick is too high, smoking will occur and soot will be deposited on the globe, wick and burner.

How to put out an oil lantern

To put out a kerosene lamp turn the wick down into the burner until the flame goes out. Turning too far can cause the wick to become unthreaded from the burner assembly completely. Remember the globe is still hot! Wait until completely cool before touching globe.

Oil lantern operation tips

- Keep the globe and burner clean.

- Glass globe and chimney become hot during use.

- Never leave a lit lantern unattended.

- Sit lantern on flat sturdy surface

- When carrying an oil lantern remember it is hot

- Only use approved lamp oil indoors.

- Burn with a moderate flame.

- Occasionally drain and wash the oil fount to free it from sediment.

- Does the globe have any cracks or chips?

- Clean the burner. Soak it in white vinegar once and awhile.

- Remove char from wick, wick holder and burner holes.

- Is there still enough fuel in the lantern? Refill if needed.

- Is my wick long enough? Replace if needed.

Storing lanterns

If you store your lantern outside in extreme temperatures, condensation will form inside the fuel front. The kerosene will float on top of the water and the inside bottom will rust. If you want to store lanterns outside in an unheated space dump the fuel out. If you store inside, dump the fuel every year or so to keep it relatively fresh. You can store lanterns in original containers or other cardboard boxes.

The differences of Dietz and V&O lanterns

How you want to use the lantern will help you decide which brand is best for you. V&O lanterns provide just as much light as their Dietz counterparts at a fraction of the cost. The metal to construct V&O lanterns is thinner. If you're going to be carrying the lantern around while camping or operating in spaces where it could get knocked around, you will be better off with the more expensive and durable Dietz lanterns. V&O lanterns will serve you well where impact damage is less likely. V&O oil lanterns are best in relatively stationary situations - hanging on a hook, carrying gently in the summer, or adding charm as table centerpieces.

Construction details of how Dietz and V&O lanterns are made are provided in the remaining text of this answer. Most oil lanterns are made with crimped tin-plated steel sheet metal. Hurricane oil lanterns or cold-blast lanterns can also be made with brass and copper.

Dietz lanterns are made with plates of thick tin-coated steel finished with a hard-wearing lacquered enamel color to prevent rust. Interior fuel tanks are plated to thwart rust. The durable lantern construction facilitates seamless operation; even in lawless weather conditions. The burners, like the fuel tank interior, is made with tin that doesn't rust and withstands a heated flame.

V&O lanterns work well and provide a lot of light. They do not leak kerosene like cheaper lanterns. V&O lanterns are made with thinner plates of tin-coated steel. An enamel color finish is also applied to prevent rust. Tanks and burners are too made to prevent rust. It has to be said: the general fit and overall quality of these lamps is less than Dietz. A little adjusting improves minor manufacturing discrepancies. You'll want to make sure all vent holes are unobstructed for optimum air flow; sometimes they are clogged in the manufacturing process. Also check to determine a tight globe to burner connection or "throat"; minor adjustments with pliers can make a better flame and brighter light.

Where are Dietz Lanterns made?

In 1956 the lantern division of the R.E. Dietz company moved to hong kong in 1956 and to China in 1982. Today the factory operates from Jiangsu, China after the last move in 2005, while the offices are still in Aberdeen, Hong Kong.

Dietz lanterns were made in the United States until 1956. When the Dietz factory moved to hong kong they no longer stamped patent and production information onto lanterns.

Lanterns made before 1956 were manufactured in Syracuse, N.Y and New York City. Find the "M" or "S" patent date located under the production date, usually stamped on the top part of the air tube on the right of the fuel cap or on the center air tube on hot-blast lanterns. See table two for what we can tell you about your lantern.

| Table. 2 Dietz Patent Stamps | |

| Stamp | Dietz Lantern Factory |

| M | Dietz New York City "Main" Factory #1 |

| S | Dietz Syracuse Factory #2 |

V&O Lanterns today are made in China. In 2005 the V&O company brand was bought by 21st century inc.